Module 6: Chain Saw Use and Safety

Welcome to the Home Study Module on Chainsaw Use and Safety.

Welcome to the Home Study Module on Chainsaw Use and Safety.

This module is designed to provide technical information and skills training for woodlot owners. If you study the lessons carefully and attend the workshop you can expect to:

1) greatly reduce accidents. Should an accident occur, you will be better prepared to handle it.

2) Be more efficient in your chainsaw technique.

3) Be able to do a better maintenance job on your saw.

This course can be of great value to you, but only if you take the time to study it. There is no magical way of becoming safety conscious. It takes effort to gain the technical knowledge to become a safe chainsaw operator.

Set aside a definite time for study. Read through the lessons carefully at your own speed. Don't do too much at one sitting. When you get tired, take a break.

In addition to the home study lessons, there will be a workshop for you to attend. This workshop will provide you with an opportunity to practice your skills and ask questions.

"The Professional at Work in Nova Scotia Forests" - a manual of the Code of Practices for the forest industry is also available. It has been published by the Department of Labour under the Occupational Health and Safety Act. Copies are available from the Nova Scotia Government Bookstore.

The original text for this course was made possible by the teamwork of a large number of people from the following organizations: LaHave Forestry Consultants, St. John Ambulance, Scott Worldwide Inc., N. S. Worker's Compensation Board, Nova Scotia Community College Lunenburg Campus, N. S. Department of Natural Resources, N. S. Department of Agriculture and Marketing, and N. S. Department of Labour.

Lesson One - Safety Equipment and Clothing

INTRODUCTION

The chainsaw is no longer the exclusive equipment of professional forest workers. It is commonly used by woodlot owners and casual users. Consequently, there has been an increase in the number of chainsaw injuries. Most injuries result from the lack of knowledge, skill, judgment. Adequate training for both the casual and professional user is the key to safe use.

Before we discuss the various cutting techniques, it is essential that you read and fully understand the following section on safety equipment and clothing.

THE SAFETY-EQUIPPED SAW

Although modern chainsaws are similar in basic design, some lack essential safety features. Make sure your saw is equipped with the following:

Throttle control lockout

Throttle control lockout

Prevents accidental acceleration of the saw. The lockout must be depressed before the throttle can be activated.

Chain brake

By stopping the chain in a fraction of a second, the chain brake can help avert possible injury from kickback. (Kickback is discussed in Lesson 2 )

Chain catcher

Reduces the distance a broken or dislodged chain will whip back towards the operator.

Anti-vibration system

Anti-vibration system

Protects the operator from the effect of saw vibration which can lead to loss of sensitivity in the fingers and possible circulatory disorders.

Rear handguard

Rear handguard

Protects the right hand from a broken or dislodged chain.

Safety chain![]()

Protective guard links or sloping depth gauges in a safety chain reduce the risk of kickback.

Safety guide bar

The four guide bars are described below:

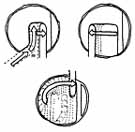

Sprocket nose:

Sprocket nose:

Conventional guide bar permitting tighter chain, less heat from friction and reduced chain wear.

Guard Tip: Same features as sprocket nose but with greatly reduced kickback zone therefore safer. However, the bar cannot be rotated to promote even wear and longer life.

Slim Line: Entire bar is narrow thus reducing bar tip radius and kickback zone. Most recommended type.

Hardnose: NOT recommended because of large kickback zone, looser chain, increased friction at nose and decreased chain life.

PERSONAL PROTECTIVE EQUIPMENT

Select work clothes on the basis of safety, protection and comfort. Clothes should be comfortable but never loose to interfere with the safe use of the saw. The material should be light, strong, capable of keeping you dry and warm as well as allowing excess heat and moisture to escape.

Many synthetic fabrics, cotton and wool products are available but rarely will they meet all your requirements. It is necessary to mix and match clothing for best results. Using a chainsaw is hard work. Therefore, wear layers of clothing that can be removed one at a time to control your body heat. This is very important during colder months.

Head

Head

A hardhat must be worn to protect your head from falling limbs, dead stubs or other hazards. It should be light, comfortable and a highly visible color (e.g. orange, yellow, or bright red). A Canadian Standards Association (CSA) approved hardhat is recommended. The shell and suspension should be checked for any visible damage before each use. Discard any hardhat that is cracked, dented, or cut. Replace the suspension if it has torn or broken threads. Never put insect repellent, paint or oil on your hard hat or drill holes in the shell. These changes will weaken the shell and reduce the protection it provides. Never leave it on the rear window shelf of a vehicle. Intense sunlight will affect its protective quality.

Eyes

Eyes

Eye protection is essential to guard against injuries from branches and flying particle. The most common protective is a safety mesh visor made of nylon or metal. The visor will prevent eye damage and allow you to keep your work in full view. Safety goggles or safety glasses are acceptable alternatives. If you choose safety glasses, select the type with wrap-around lenses, or side shields.

Ears

Ears

The noise produced by a chainsaw is above 85 decibels and will cause permanent damage to your hearing. Even the newer saws that are much quieter may injure your hearing with constant exposure. It is necessary to wear earmuffs or ear plugs to reduce the noise level. Earmuffs also protect the external ear. Clean the soft plastic pads and foam inserts periodically with soap and water. Always replace them before they become old and brittle.

Hands

Hands

Chainsaw gloves or mitts are worn to protect hands from injury and for warmth. Some forest workers wear gloves with added safety padding on the back of the left hand. Some prefer mittens with a separate index finger to operate the throttle. Gloves are not required safety equipment in Nova Scotia.

Legs

Since many chainsaw accidents cause injury to legs, you must wear protection. Three types of protection include:

![]() Safety pants: Provide the best protection. They have cut-resistant ballistic nylon sewn into the whole front of the pants. The protected area should be from the bottom of the heel (while in a standing position) to below the waistband. Newer styles also have ballistic nylon sewn into the lower back section of the legs.

Safety pants: Provide the best protection. They have cut-resistant ballistic nylon sewn into the whole front of the pants. The protected area should be from the bottom of the heel (while in a standing position) to below the waistband. Newer styles also have ballistic nylon sewn into the lower back section of the legs.

Chaps: Cut-resistant ballistic nylon leg pads that strap over work pants.

Safety pads: Cut-resistant ballistic nylon pads that fit into pockets inside pant legs or are sewn in. Generally they give good protection but sometimes they unhook and slump in the pocket leaving the legs unprotected.

Feet

Feet

Wear boots with CSA Class A steel toe caps and non slip soles. Many forest workers prefer boots which feature ballistic nylon protection in the front similar to safety pants or chaps. Work boots also protect the foot from painful crushing injuries.

*******

REMEMBER a chainsaw is not a toy! It can seriously injure or even kill. NEVER use your saw without wearing all your personal protective clothing. NEVER use a saw that is not equipped wit all safety features.

Module 6 - Lesson One Quiz

| Questions: | 10 |

| Attempts allowed: | Unlimited |

| Available: | Always |

| Pass rate: | 75 % |

| Backwards navigation: | Allowed |

Lesson Two - Safety Practices and Hazards

TRANSPORTING THE SAW

Whenever you transport the saw, it should be fitted with a chain guard to protect yourself and to prevent damage to the chain. Walk with the bar pointing behind you so you'll be protected from both cutters and the hot muffler if you slip or fall.

Apply the chain brake when carrying the saw. This is an added precaution even though the chain should not normally rotate while the saw idling. Note: Allow the chain rotation stopped to decrease before applying the chain brake to reduce unnecessary brake wear.

FUELING

Check the manufacturer's manual that comes with your saw to make sure that you are using the proper oil/fuel mixture. To avoid spilling gas on the hot engine a funnel with a strainer can be used to fill the tank. Never refuel with the engine running. Start your saw at least 3m (10 ft.) from the refuelling spot.

Always fill the oil tank at the same time as the fuel tank. Having the oil tank run dry will severely damage the chain and bar. Heavy weight (or summer oil) should be used at temperatures above 5 Celsius (40 F), light weight (or winter oil) at lower temperatures. In all cases, follow the manufacturer's manual. NEVER smoke while refuelling the saw. Have a fire extinguisher nearby and avoid spilling oil or fuel while refilling.

CHECKING THE SAW

Get in the habit of checking your saw before you begin to work. As discussed in the previous lesson, check the following items:

- Throttle control lock-out

- Chain brake

- Chain catcher

- Anti-vibration system

- Rear hand guard

Also inspect:

- Chain tension

- Depth gauge settings

- Nuts and bolts for tightness

By taking 10-30 seconds to inspect these points you may find an unexpected problem that could cause an injury. this inspection should be done for any saw whether it was used yesterday or last year.

When checking the chain tension, ensure that the chain is snug on the bar but loose enough to be pulled around the bar by hand.

NEVER tighten the chain while the saw is idling.

It is best to tighten the chain when it has cooled down. Adjusting a hot chain will cause a very tight fit when the chain cools down and contracts.

Breaking in a New Chain

Most new chains are coated with a rust inhibitor but this is not a lubricating oil. Therefore, a new chain should be soaked in lubricating oil (preferably overnight).

Break in the new chain following this procedure:

-

Place the chain on the guide bar and tighten snugly while still allowing the chain to be turned freely by hand.

-

Start the saw and run the chain for a couple of minutes without cutting wood to allow the parts to loosen.

-

Allow the saw to cool down and then adjust the tension.

- Make a few cuts in a log to try the chain, then allow it to cool down before read justing the tension.

NOTE: This readjustment of the tension may take several more cuts, cool downs and adjustments before the chain stops stretching and stays tight.

STARTING PROCEDURES

Starting a chainsaw may appear fairly routine but there's more to it than just pulling the starter cord. Accidents can occur, especially when the chain starts racing around the bar once the engine is running. Before attempting to start your saw ensure that:

Starting a chainsaw may appear fairly routine but there's more to it than just pulling the starter cord. Accidents can occur, especially when the chain starts racing around the bar once the engine is running. Before attempting to start your saw ensure that:

-

an operating check is made of all safety features.

-

the bar and chain are in place. Starting a saw without them can result in the clutch mechanism flying off and causing injury.

- the saw is well away from any objects that may catch in the chain.

Cold Start

Cold Start

The safest and most common method is starting the saw while it is firmly on the ground. Ensure the ignition switch and choke are both "ON" and the throttle control latch is engaged. Steady the saw by placing your right foot through the rear handle. Grip the front handle with your left hand and the starter cord with your right hand.

Pull gently until you feel some resistance from the starter mechanism. Then, use a quick sharp pull to start the engine. Keep hold of the handle as the cord retracts. Rev the engine briefly to release the throttle control latch and let the saw idle.

Warm Start

If the engine is warm, the saw must be started by one of two alternative methods. Neither the choke nor throttle control latch need to be used.

Method 1

Starting on secure footing with your feet slightly apart. Hold the front handle with your right hand so the starter side points away from you. Starting the saw with the starter side towards you can result in serious injury.

Grasp the starter handle with your left hand. Lift the saw by bending your right arm. Lower the saw quickly while pulling the starter handle.

Method 2

Method 2

Grip the saw's rear handle between your thighs.

Holding the front handle firmly with your left hand, pull the starter handle with your right. These two methods are particularly suitable when brush or ground conditions make it difficult to start the saw on the ground.

HANDLING THE SAW

Stand with your feet planted firmly on the ground and legs spread about shoulder width apart to give you a balanced stance. Boots with non-slip soles should be worn to prevent slipping and injury.

Grip the saw with your thumb around the front handle not over it. A loosely-held saw can be easily jerked out of your hand during kickback.

Keep your wrists straight to reduce strain and muscle fatigue. Rotate your right hand whenever you have to change the cutting position of the saw. Use your thumb to control the throttle when the saw is on its side. This may seem difficult at first, but it becomes easier with practice.

Hold the saw firmly and close to your body. Keep your arms bent. Outstretched arms will tire you more quickly and keep you off balance. To control the saw better and relieve the load on your back and arms, use your body and the tree stem to support the saw while cutting. (Remember, your hands and arms are used mainly for guiding the saw and not bearing its weight). This is sometimes the most difficult part to learn. However, resting the saw body against the stem or your body makes common sense and is one of the most positive comments about modern cutting practices.

Never saw above your head! In this position you cannot adequately control your saw. A good rule of thumb is to never raise the tip of the bar above your head.

When cutting always maintain a firm, balanced stance and ensure the saw is running at full throttle. This will prevent you from being jerked off balance.

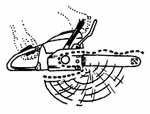

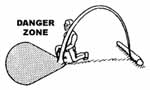

Kick-back:

The dangerously sudden and uncontrollable movement of the saw guide bar during kick-back is a common cause of chainsaw injuries. It occurs when the nose of the bar comes in contact with the tree or any solid object. The chain jams and pile sup at the point of contact forcing the saw guide bar violently back and up towards you. Kick-back can cause serious injuries.

The following points can help you avoid kick-back:

- Pay attention to what you are doing

- NEVER cut with the kick-back zone

- Use a safety chain

- NEVER file the depth gauges too low (use depth gauge tool)

- Maintain a strong grip on the saw at all times (both hands)

Muscle and Joint Strain

Using a chainsaw involves a lot of physical work that puts a heavy strain on your back and joints. Always use safe lifting methods to avoid injuring yourself. Keep your back straight, lift with your legs. Always grip the object securely and don't twist your back. Fifty-five percent (55%) of all injuries are caused by poor lifting and carrying techniques. The muscles in your legs are the strongest in your body; the muscles in your lower back are the weakest.

Fatigue

Fatigue is one of the most common reasons for injuries. You must always be alert when operating a chainsaw. The majority of injuries occur in the mid to late afternoon when you and your muscles are becoming tired after working all day.

Take the time now to learn how to use the chainsaw safely. With the seriousness of saw injuries, a few moments learning safe practices can save a lifetime of regret.

*****************

Module 6 - Lesson Two Quiz

| Questions: | 10 |

| Attempts allowed: | Unlimited |

| Available: | Always |

| Pass rate: | 75 % |

| Backwards navigation: | Allowed |

Lesson Three - Sharpening

SELECTING THE CHAIN

For normal woodlot operations, there are several types of chain available. Always purchase a safety chain as discussed in lesson one, but consider the following when choosing a chain most suitable for your work.

Chain Pitch

Chain Pitch

The pitch is the size of the drive link and is obtained by measuring the distance between any three adjacent rivets and dividing by two. Both the chain and sprocket pitch must be the same to get a good fit and to prevent damage to the chain, sprocket and bar. The fit can be tested by hand meshing the sprocket and drive links or by using a sprocket gauge.

Chain Gauge

Chain gauge is the thickness of the drive link. To fit properly, the drive links must match the width of the bar groove and fit snugly without touching the bottom groove. Place the drive links in the bar groove to check the fit. It is best to check with the chain dealer or product box for chain gauge thickness.

Chain Length

The chain length is expressed by the number of drive links. If an old chain is still on your saw, this length (number of drive links) can be determined by a simple count. The chain length must match the length of the guide bar to ensure a proper fit and to prevent damage to bar and sprocket.

CHAIN TENSION

CHAIN TENSION

An improperly tensioned chain is dangerous and is the cause of most chain problems.

To adjust the tension, shut off the saw and loosen the bar nuts. Wearing gloves to protect your hands, grasp the bar tip and lift. Place your screwdriver in the adjustment bolt and turn clockwise to tighten the chain or counter clockwise to loosen it. The chain should be snug with the bottom of the bar. With older saws you may need to keep your grip on the bar to maintain its position while tightening the bar nuts. Once tightened, the chain should easily be turned around the bar by hand.

Installing the Bar, Sprocket and Chain

To begin the process of installing a new chain, bar or sprocket, check that all the parts match for pitch, gauge and length.

-

Remove the sprocket-clutch cover as well as the chain and bar. (Keep all parts neatly in the order you remove them.)

-

Secure the flywheel (follow manufacturers instructions) and remove the sprocket and bearing

- If you have a spur sprocket attached to the clutch drum, the whole piece must be replaced.

- With a rim sprocket, only the rim sprocket and bearing need replacing.

-

Always assemble the components in the order they were removed.

-

Grease and replace the bearing.

-

With the rim sprockets, older models may have a more open side which should face away from the engine when placed on the hub spline. Newer rims can be placed either way.

-

Place the bar on the saw and align it with the studs. Important: Oiler hole in the saw body must be aligned with oil hole in the bar.

- Place the chain on the bar and over the sprocket. Pull the chain a few times to ensure that the drive links set in the sprocket properly. Pull the bar forward to tighten the chain around the bar and sprocket. Adjust the tension as discussed earlier. Note: It is a common mistake with beginners to put the chain on backwards. The chain teeth should be facing away from the saw body on the top portion of the bar.

Lubrication

Lubrication

To eliminate wear or seizing of components, it is necessary to oil the chain and bar regularly. Use heavy weight chain oil during the summer and light weight chain oil during the winter. Medium weight oil is also available for spring and fall use. Each time you refuel, fill the oil tank. Check the owners manual to see if the nose sprocket of the bar needs to be greased. If yes, make sure that you clean the greased fitting hole of the bar.

This procedure is also important at the end of the day to prevent moisture build-up.

Do not depend on chain oil to prevent wear to the chain when it is not sharpened correctly, dull or used improperly.

Some older saws have a manual oiler which is worked with your thumb. Don't get carried away with your cutting and forget to pump oil to the chain. Adjust the amount of oil to match the cutting. Automatic oilers are common on the newer saws and they are adjusted to use approximately a tank of oil for each tank of fuel.

![]() Cleaning the Bar Groove and Oil Hole

Cleaning the Bar Groove and Oil Hole

To eliminate wasting oil and to prevent damage to the bar, the bar groove and oil holes must be cleaned daily.

Remove the bar and chain. Insert a bar cleaning tool or similar instrument into the bar groove making sure that it is touching the base of the groove. Clean the bar groove in the direction away from the nose sprocket. Clean the oil holes and groove with an appropriate cleaning tool. Replace the components and adjust chain tension.

SHARPENING THE CUTTING TEETH

A sharp and properly maintained chain is essential for safe and efficient chain saw performance.

Before sharpening, remove oil and dirt from the chain teeth. Secure the chain in the bar groove or other holding device so that the teeth won't move when you are filing.

Filing Angles

Filing Angles

The important thing to remember is consistency. All top plate angles must be the same. The angle (usually either 25 or 30 degrees) is recommended by the manufacturer. Also, are all teeth the same length? Consistent angled and equal tooth lengths will allow your chain to cut smoother and stay sharp longer.

Technique

The actual file size for a specific chain is recommended by the chain manufacturer and printed on the chain box or manual.

Place a handle on your file to make filing easier and prevent punctures to your hand. When sharpening, make sure you place the file on the tooth properly. Keep at least 10 percent of the file above the top plate of the cutting tooth. If the file is held to low, a dangerous "hook" is created. This causes the chain to grab and cut roughly, increasing the possibly of kickback. If the file is held too high, a "backslope" is created and cutting is slow.

Place a handle on your file to make filing easier and prevent punctures to your hand. When sharpening, make sure you place the file on the tooth properly. Keep at least 10 percent of the file above the top plate of the cutting tooth. If the file is held to low, a dangerous "hook" is created. This causes the chain to grab and cut roughly, increasing the possibly of kickback. If the file is held too high, a "backslope" is created and cutting is slow.

Read the manufacturer's instruction for any special sharpening requirements for the chain you're using.

Remember to press the file lightly against the cutting edge and down towards the bar. Proper sharpening "hones" the edge and doesn't remove a lot of filings.

Check the filing angles often as you sharpen all the chain teeth.

Sharpening Guides

Sharpening Guides

To overcome errors in sharpening, you may want to use a sharpening guide. Some are relatively inexpensive and surprisingly easy to use. They help to ensure the consistency needed for a smooth-cutting chain.

Some individuals can do a good job sharpening freehand (without a guide). However, they are a selected few who have mastered an art of sharpening. In a way, they have developed their ability to trouble-shoot chain problems.

Most will need some assistance to do a reasonable job. Remember, the use of a sharpening guide does not always indicate an amateur.

Sharpening Frequency

Ideally, the chain should be sharpened whenever it becomes dull. Many instruction manuals suggest that the teeth be sharpened lightly at each fill-up. How often will depend upon the species of tree you're cutting, the season of the year, the forestry treatment, and the type of chain being used. Therefore, it may be necessary to sharpen only once or twice daily.

Discarding the Chain

When a chain breaks it can cause serious injury to the operator.

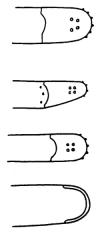

Examine the chain regularly to locate cracks or excessive wear. Common wear points include tie straps, drive links, rivets, and cutters.

Discard the chain if these checks find damage that affects the chain's strength. The type of damage will also indicate why the damage has occurred. Knowing this is important to stop unnecessary damage to your next chain.

As a general rule, seriously damaged chains are not repaired. The first break may only be the start of a regular breakage.

When you discard a chain, it is also important to check the drive sprocket. A worn or damaged sprocket will cause unnecessary wear to a new chain. Therefore, it is recommended that a new chain always be fitted on a new sprocket.

FILING THE DEPTH GAUGES

Depth gauges and the resulting depth gauge setting determine how deep the cutting teeth will "bite" into the wood. It is important that you use a depth gauge tool whenever you are filing the depth gauge.

Depth gauges and the resulting depth gauge setting determine how deep the cutting teeth will "bite" into the wood. It is important that you use a depth gauge tool whenever you are filing the depth gauge.

Refer to manufacturer's specifications for the correct depth gauge setting for your chain. All depth gauges must be the same height.

A depth gauge which is filled too low causes "choppy" cutting and greatly increases vibration, chain breakage, unnecessary wear as well as kickback and injury.

![]() Filing the depth gauges off entirely will not improve the cutting ability of the saw. The depth gauges, or modified safety links, are designed to reduce kickback. It is important that filing retain the original shape of the depth gauge.

Filing the depth gauges off entirely will not improve the cutting ability of the saw. The depth gauges, or modified safety links, are designed to reduce kickback. It is important that filing retain the original shape of the depth gauge.

Use a flat file with an appropriate depth-gauge setting tool to keep the setting within 0.0127 cm (0.005 in.) of the manufacturer's specifications. A common setting of 0.0635 cm (0.025 in.) would allow a setting on no lower than 0.0762 cm (0.030 in.). This is very difficult to judge with the naked eye.

Check the depth gauge settings every third filing and adjust if necessary.

*****************

Module 6 - Lesson Three Quiz

| Questions: | 10 |

| Attempts allowed: | Unlimited |

| Available: | Always |

| Pass rate: | 75 % |

| Backwards navigation: | Allowed |

Lesson Four - Maintenance

MAINTENANCE

Too often a good saw is ruined despite detailed maintenance instructions found in the operator's manual. Neglecting the manual's advice will not only result in shorter saw life but will also cost you money and increase the chance of injury during saw operation. You have payed good money for your saw. Read the manual and look after it!

Maintenance checks can be done daily, weekly, and monthly. Obviously, certain items should be checked more often than other items.

In this lesson, we'll discuss daily maintenance and only briefly maintain the weekly or monthly maintenance.

DAILY MAINTENANCE

Checks are best conducted at the end of the day when work is completed. If something major is found it can be repaired before the next day.

Daily maintenance shouldn't take a lot of time. The items to be included are:

![]() Guide Bar, Chain and Sprocket

Guide Bar, Chain and Sprocket

Remove the bar and chain. Inspect the bar for damage or abnormal wear (e.g. chain entry and bar rails). Clean the groove with an appropriate tool. Be sure to clean the chain oil holes in the bar and saw

Check the operator's manual for instructions on lubricating the nose sprocket. Some sprockets may not require greasing.

![]() Before reassembling, examine the chain and inspect the drive socket for abnormal wear. Clean the clutch cover to remove sawdust or debris from the chain brake mechanism. Turn the bar over to maintain equal wear on both sides.

Before reassembling, examine the chain and inspect the drive socket for abnormal wear. Clean the clutch cover to remove sawdust or debris from the chain brake mechanism. Turn the bar over to maintain equal wear on both sides.

Engine Area

Engine Area

Remove the top cover to clean two important areas.

First, ensure the cylinder fins on the engine block are clean. They are designed to help cool the engine. If the fins are dirty, heat is trapped. This can cause the engine to overheat and may result in engine failure.

Second, clean the air filter. Of all the daily maintenance checks, the air filter is one of the most crucial. It is designed to remove dust particles from the air going to the motor. Dirty air filters can cause flooding, power loss and may even cause the saw to stop, A damaged filter will allow dirt to enter through the carburetor causing internal damage.

Second, clean the air filter. Of all the daily maintenance checks, the air filter is one of the most crucial. It is designed to remove dust particles from the air going to the motor. Dirty air filters can cause flooding, power loss and may even cause the saw to stop, A damaged filter will allow dirt to enter through the carburetor causing internal damage.

Improved technology on some newer chainsaws has greatly reduced the amount of dust particles being deposited on the air filter. These filters only require cleaning up to once a month.

Clean filters with either compressed air or warm soapy water. Carry a spare clean filter and replace daily. Generally, filters can be separated into two pieces. Compressed air should be blown outward through the screen to dislodge dirt particles. For a good cleaning, warm soapy water will be needed along with a soft, bristled toothbrush.

Rinsing the filter in clean unmixed gas is an alternative cleaning method, though not as good.

Finally, visually check the muffler mounting screws and the cleanliness of the screen. Screens (or spark arresters) are required by law. They reduce sparks that may come from the engine. It may be necessary to clean this screen, especially when the saw is new. Cleaning is rarely needed once the saw has been "broken in".

Starter Assembly

Starter Assembly

The starter side is not removed during daily maintenance. However, there are some item to check.

Ensure that air passages on the starter side are clean and will allow air into the saw. Remember, most of the air used by the engine is obtained from these air passages.

Pull the starter cord to check its condition. (Make sure the ignition switch is "OFF"). Look for worn sections and ensure it returns fully. The handle should sit upright when the cord is full returned. If not, readjust the spring tension.

Throttle Area

Although not a cleaning job, check the throttle and the throttle lock for proper operation.

Visually inspect all nuts and bolts on the saw. Frequently, bolts can loosen due to vibration. This is particularly true when the saw is new. Always keep a few extra bolts and nuts in your tool kit.

Fuel Lubrication

Fuel Lubrication

The chainsaw has a two stroke engine which requires blended fuel. The proportion of mix oil to gasoline varies according to the saw manufacturer's instructions. The most common ratio is 40-1 which represents 40 litres of gas to 1 litre of oil. For practical handling, 10 litres of gas are usually mixed with 250mL prepackaged container of mix oil.

Only use the manufacturer's recommended mix oil or another brand which meets the manufacturer's specifications.

Shake the container each time you fill the tank to reduce condensation buildup, especially in cold weather.

For overnight storage, fill the tank to reduce condensation buildup, especially in cold weather.

![]() Fuel is a highly flammable substance and should be handled carefully. Store it only in approved safety container and never expose it to flame or spark.

Fuel is a highly flammable substance and should be handled carefully. Store it only in approved safety container and never expose it to flame or spark.

Start the saw, let it warm up and finally check that the chain is receiving oil by holding the bar tip about 25 cm (10 in.) of a clean surface. Also verify that the chain brake is working properly.

Daily maintenance will take 10-15 minutes to complete but will assure you of trouble free operation the next morning.

WEEKLY MAINTENANCE

With the extra number of hours that a chainsaw operates during a week, maintenance must be slightly more detailed than the daily maintenance previously discussed.

These items to be checked weekly should be cross-referenced with your owner's manual which may have specific recommendations.

Spark Plug

Remove the spark plug from the engine block to check, clean, and if necessary re-set the gap to manufacturer's specifications. Always use a proper spark plug tool to remove the plug and a feeler gauge to measure the gap. Improper tools can cause cracks in porcelain and chips from the top shaft of the plug.

Do not over tighten the spark plug.

Starter Assembly

Remove the starter assembly to give the unit a good cleaning from the inside. Verify the condition of the starter cord.

Inspect the pulley and bearing for wear. Clean and apply light oil to the starter spring.

Take the opportunity to thoroughly clean the flywheel cooling fins. A screwdriver, pointed stick or similar device will be needed to remove the dirt, sawdust, and baked deposits which will not brush off.

A similar method may be required on the main engine block cylinders as well. However, do not cause breakage by forcing the cleaning tool between the vanes or fins.

Chain Brake Assembly

As with daily maintenance, the assembly must be removed from around the saw. Inspect the brake mechanism for excessive wear or cracks. Also grease the clutch bearing to provide lubrication between the bearing and the engine shaft. Check the manufacturer's instructions for further information. Some models can easily be greased with a grease gun while others may require specific procedures.

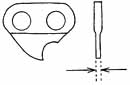

GUIDE BAR

The chain has to move around the bar in an upright position if it is to cut safely and efficiently. Therefore, the bar must be straight and the bar rails which support the chain must be maintained properly. Some of the most common causes of bar damage include:

-

Dull teeth force the chain to overwork and heat up causing burned spots.

-

Uneven top plate filing of the teeth will cause uneven wear to the bar rails.

-

Excessive bore cutting will cause wear to the guide bar nose (Note: Bore cutting is covered in Lesson Five).

-

A slack chain will hit against the bar causing burning and indentation to the underside of the bar nose.

-

Too much tension when the chain is running will cause the bar nose and bar rails to wear excessively.

-

If a tree should lean back on the bar, it could bend the bar or pinch the rails.

-

Lack of lubrication, improper tension, or a dull chain can result in excessive heating of the bar and may cause cracking and chipping of the rail.

To check for uneven rails, place a T-square or similar right angled tool against the guide bar.

You can repair uneven rails if the condition is not severs. Place a bar in a vise and use a flat file 20-30 cm (8"-12") with both hands. Remember to keep the file flat. Continue on one side then the other until the rails are even. The bar groove has a minimum depth equal to the depth of the drive link depth. Don't file the rails too low.

To check for thin rails remove the chain and sight along the guide bar rails. Thin rails are usually low. If the rails are thin and uneven, replace the bar.

Burrs caused by normal use or running a dull chain may be removed by filing. The bar should be placed on a flat surface and file must be held flush with the surface of the bar to ensure a right angle at the rails. Failure to do this or filing at an incorrect angle will round the edges of the rails.

Burrs caused by normal use or running a dull chain may be removed by filing. The bar should be placed on a flat surface and file must be held flush with the surface of the bar to ensure a right angle at the rails. Failure to do this or filing at an incorrect angle will round the edges of the rails.

If you have excessive wear, check the list of causes of bar damage and correct the problem before you use the saw.

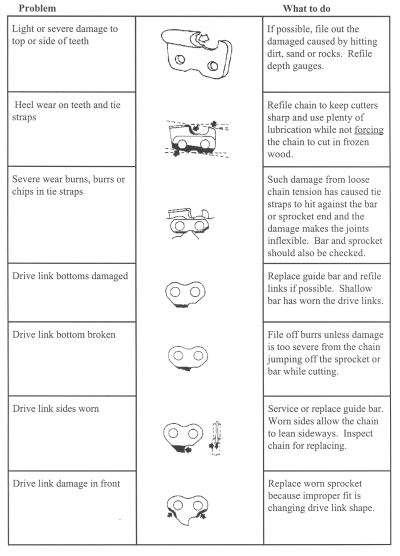

GUIDE BAR DAMAGE CHART

CHAIN

The chain can make or break the usefulness of the chainsaw. The chain must be sharpened properly and maintained regularly to ensure efficient and safe operation.

Suggestions for sharpening the chain have already been discussed in Lesson three. However, there are other parts of the chain that should be examined.

Check for wear or damage on the teeth, tie straps and drive links. Most damage to these chain parts is caused by either improper chain tension or poor sharpening methods. Some damage can be can also be caused by the chain coming in contact with material other than wood.

To check for specific wear problems, refer to the chain damage chart. Damage can usually be traced back to the source of the problem for proper correction. When actual cracks appear in any of the parts, however, the parts or chain must be replaced.

CHAIN DAMAGE CHART

CARBURETOR

The carburetor is one of the most important parts of the chainsaw. It controls the performance of the engine and ultimately the cutting efficiency of the saw. Unfortunately the carburetor is usually the first thing operators check when the saw isn't operating properly. Without careful inspection, however, adjusting the carburetor can cause more harm than good.

Do not adjust the carburetor when something is wrong. Generally, the carburetor will rarely need adjustment once it is set properly.

There are other parts of the saw that should be checked first. These include:

| Air Filter: | This is the most common problem of "suspected" carburetor problems. Clean the filter on a daily basis. |

| Fuel Filter: | If the filter plugged or restricting the fuel? |

| Air Vent: | Is the vent plugged? |

| Fuel Line: | Is it cracked and allowing air into the fuel mixture? Has the line collapsed? |

| Fuel Tank: | Is the gas tank full? Does it have properly mixed fuel? Has dirt or water entered the tank and moved through the line to the carburetor? |

| Screws: | Have the screws holding the carburetor to the engine block vibrated loose? |

| Gaskets: | Has the gasket between the carburetor and engine shifted or deteriorated? |

| Spark Plug: | Is the plug properly seated and the gap set properly? Is the wire or harness worn cracked or loose? |

Now that you have inspected the above items and are confident that they are not the problems, the carburetor can be adjusted.

Setting the Carburetor

Adjusting the carburetor is not easy. Some individuals have developed the ability to set the carburetor by ear. These individuals are more the exception than the rule. This is particularly true of new lighter chainsaws where the speed of the chain is more important than the torque of the engine. As such, the rpms of the engine have a narrower "window" of operation. Anything above this range will cause the saw to run too lean and eventually cause premature engine failure. A tachometer is needed to correctly set the rpms of the engine.

The following is a general procedure for setting a diaphragm carburetor. Remember, all settings and sometimes the procedures for setting a particular chainsaw must follow the manufacturer's recommendations.

| 1.a. |

Using the correct size screwdriver, turn the HIGH and LOW speed adjusting screws clockwise until they are seated. DO NOT ATTEMPT TO EXERT FURTHER PRESSURE OR THE NEEDLE VALVE SEATS MAY BE DAMAGED. |

| b. |

Turn the HIGH and LOW speed adjusting screws anti-clockwise by the amount recommended by the manufacturer. The saw should start at these settings. Start the saw and warm up the engine by making several cuts. |

| 2.a. |

Adjusting the Low Speed Jet It will be necessary to increase the engine speed by turning the throttle adjusting screw clockwise until a fast idle is achieved before starting this adjustment. With the saw running at a fast idle, turn the low speed adjusting screw very slowly in (clockwise) until the saw begins to falter. Turn the low speed adjusting screw very slowly out (counter-clockwise) through the point of fast idle until the saw begins to falter again. The fast idle point is generally half way between the falter points. Turn the low speed adjusting screw very slowly in (clockwise) until the fast idle position is reached. |

| b. |

Checking the Low Speed Setting Open the throttle quickly several times; if the saw picks up quickly without hesitation the low speed jet is correctly set. If it hesitates, turn the low speed screw slightly out (counter-clockwise) to enrich the mixture and check again. Turn the saw over onto its side; if the engine falters or stalls, close the low speed screw slightly until the fault disappears. |

| 3. |

Adjust the throttle adjusting screw to achieve correct idle ensuring that the chain does not move around the bar when the saw is idling. |

| 4.a. |

Adjusting the High Speed Jet With the throttle fully open, turn the high speed adjusting screw very slowly until the pitch of the engine noise rises to indicate maximum engine speed. Turn the high speed adjusting screw out slowly until the high pitched note changes into a deeper "bubbling" note. Finer adjustment will be required by turning the high speed adjusting screw in slightly while still maintaining the "bubbling" note of the engine. |

| b. |

Check the High Speed Setting The high speed setting can be checked by cutting into a log at full throttle. As the saw is cutting, (i.e. under load) the saw should run smoothly. IT IS IMPORTANT THAT THE SETTING IS NOT TOO WEAK. THIS WILL CAUSE THE ENGINE TO OVERHEAT AND CONSIDERABLE MECHANICAL DAMAGE MAY RESULT. |

| 5. |

Check both settings after 1-2 hours.

|

Spare Parts

Always carry spare parts with you at the job site. It will save you a lot of time and money rather than stopping work to drive to the nearest repair shop.

Generally, spare parts that will eventually be needed include:

Air Filter

New Saw Chain

Starter Rope (and handle)

Spark Plug

Extra Guide Bar Nuts

Extra Casing and Cover Screws

Starter Spring

Spare Files

You may want to expand this list to include other items you think are important. Some individuals like to carry an extra guide bar or sprocket. Sometimes, particular parts of a small engine may break. If so, you should add a spare to your spare parts bag.

Always carry your tool kit with you. Most new saws come equipped with a tool pouch providing the basic items to do minor repairs.

Module 6 - Lesson Four Quiz

| Questions: | 10 |

| Attempts allowed: | Unlimited |

| Available: | Always |

| Pass rate: | 75 % |

| Backwards navigation: | Allowed |

Lesson Five - Felling

Felling is the job of cutting a tree to bring it to the ground. As simple as it sounds, there are many factors to consider. It takes a lot of practice to put a tree where you want it and avoid causing unnecessary damage to the tree, the saw or injury to yourself.

ASSESSING THE SITUATION

ASSESSING THE SITUATION

Take a few minutes to assess the tree you plan to fall. Some trees are more difficult to assess than others. However, since a large sawlog tree may weigh a ton, you must be confident of where it will be falling.

Although trees grow upright, few stand perfectly straight. A lopsided crown, broken top, dead limbs or prevailing winds can all affect the direction a tree will fall.

In addition to considering the above items, also check for ground debris and windfalls that may interfere. If a tree is hung up into another tree, get a machine to safely take it down or clearly mark the area for others to avoid.

ESCAPE ROUTE

ESCAPE ROUTE

It is crucial to have an escape route available for every tree you fall. It is best established at a 45 degree angle diagonally backwards

Clear away brush and small trees from around the base of the tree to be felled. Avoid using the tip of the guide bar to reduce the potential risk of kick-back. A clear work area will ensure firm footing and no interference with your saw when making the notch and back cuts.

As you complete the backcut and the tree starts to fall, retreat into the escape route. Do not turn your back to a falling tree. In some cases, it may be necessary to make two escape routes.

Failure to properly assess the tree or move into an escape route has resulted in the deaths of several forest workers in Nova Scotia. Most accidents or fatalities are caused by carelessness or an error in judgment.

PRE-LIMBING

Prelimbing is the removal of the lower branches of a standing tree to permit easier felling.

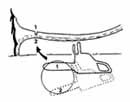

Hold your saw with the guide bar parallel to your shoulders and your arms slightly bent.

Keep the tree trunk between you and your saw. If kick-back does occur, the chain will be directed away from you. With heavy limbs, it may be necessary to begin prelimbing as shown below. Keep your body weight forward to hold the saw against the stem.

Always cut with a downward motion using the pulling chain (underside of the guide bar).

Never attempt to remove branches above shoulder height. Progress around the tree using full throttle each time a downward cut is made. When you finish, you should be in a position to begin the notch at the front of the tree.

The prelimbing procedure does appear to be awkward, but it is a safe and effective method used by trained forest workers. A demonstration by a competent worker would illustrate the merits of this method.

NOTCHING

A great deal of variance exists with the type of notch (or undercut) used for felling trees. Some are narrow, others wide, while some are just a saw cut placed without any purpose. Some people do not use a notch, thus exposing themselves to extremely hazardous situations.

There is a correct way to notch.

What is a Notch?

A notch consists of two cuts which meet exactly. It's made as low as possible at the base of the tree and toward the direction of fall.

What is its Purpose?

What is its Purpose?

Notching determines the direction a tree will fall, and the openness of the notch determines how well the tree will be guided to the ground.

An open notch allows the tree to fall freely in the desired direction while still being attached to the stump by the hinge or holding wood (much like a door is guided by its hinges).

A narrow opening will close too soon and force the hinge to break off. The result will be a tree falling off-target and possibly lodging in another tree.

Many experienced forest workers attending training programs to upgrade their skills have said: "That new notching technique is a great improvement over the old way I've been doing it."

Basically it involves making the upper notch cut first and then the lower one. This is directly opposite to the traditional method most workers have learned.

How to do it

Work facing the felling direction. This allows you to saw the notch and the back (or felling) cut from the same side of the tree.

Take up a firm stance slightly behind the tree. To help you work more comfortably, rest your left shoulder against the tree and if necessary, support you right arm on your right knee.

Take up a firm stance slightly behind the tree. To help you work more comfortably, rest your left shoulder against the tree and if necessary, support you right arm on your right knee.

Grasp the left corner of the front handle to help make a 70-degree angle for the top cut. Line up the felling direction using the sighting lines on the saw.

Begin the top cut, make sure the cut is level and extends deep enough to make an adequate hinge.

With your left hand positioned midway along the side of the front handle, use the pulling chain to begin the bottom cut.

Keeping the guide bar horizontal, either begin to saw at the far end of the top cut and draw the saw toward you or saw from the near end and pivot the guide bar into the tree.

To check that the bottom cut isn't made too deep, sight down the saw kerf of the upper cut.

To check that the bottom cut isn't made too deep, sight down the saw kerf of the upper cut.

Both cuts should meet exactly. The depth of the notch should be approximately 1/4 of the tree diameter.

Both cuts should meet exactly. The depth of the notch should be approximately 1/4 of the tree diameter.

Note: Some workers prefer to make an angled bottom cut resulting in a 90-degree notch. This can be a useful technique when you need to control the tree over a longer range of its fall, for example, when felling a tree on a downhill grade.

THE BACK CUT

Now use the pushing chain on top of the guide bar to make the back cut. This cut should be level with or slightly above the bottom of the notch. This makes it easier to correctly judge the thickness of the hinge.

Begin the cut on the far side of the tree and complete it by pushing the engine forward toward the notch on the near side of the tree.

Insert your felling lever or wedge before the tree settles back and the saw kerf closes.

Be sure to leave sufficient hinge wood of even thickness to control the tree as it falls. One inch to a ten inch diameter tree is an approximate rule of thumb. However, thicker hinges may be required for trees with heart rot.

Withdraw the saw carefully and place it in a safe place. Use the felling lever, with your knees bent and back straight.

As the tree begins to fall, step into the escape route, watch out for any falling branches or tops.

As noted earlier, it is suggested that the notch and backcut be made from one general position. Although the technique is more efficient, it is also acceptable to cut the notch from the other side. This would be advisable if other trees or objects (eg. a rock or stump) interfered with notching from the suggested side.

This new notching technique will take a little practice, but once you've mastered it you'll be a safer and more productive worker.

TECHNIQUES FOR LARGER TREES

When dealing with trees of different diameters, the notching technique may have to be modified.

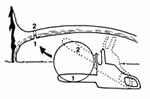

In the case of large diameter trees it will be necessary to cut the notch from both sides of the tree.

Trees with a diameter up to twice the length of the guide bar can be cut using the boring technique. After the notch has been cut, use the lower section of the guide bar tip to make a small cut in the tree. Once the cut is started, slowly straighten the saw to bore into the centre of the tree. When the bar is inserted completely, cut toward the hinge wood. Complete the backcut by sawing around the tree while leaving the proper hinge intact on both sides.

Trees with a diameter greater than twice the length of the guide bar require an extra step. After the notch has been made, cut through the throat of the notch and remove the centre portion of the hinge. The diagrams show the correct procedure which still allows sufficient hinge wood to control the tree as it falls.

Trees with a diameter greater than twice the length of the guide bar require an extra step. After the notch has been made, cut through the throat of the notch and remove the centre portion of the hinge. The diagrams show the correct procedure which still allows sufficient hinge wood to control the tree as it falls.

FOREST WORKER TOOLS

For years forest workers have used a wide range of peavies, pulp hooks, wedges and samsons to help make their work easier and safer. More recently, workers have been introduced to felling levers, hooks and tongs, and loggers' tapes. Used correctly, these tools simplify felling, thinning, and handling of wood.

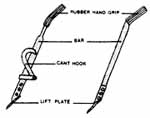

Felling Lever

A felling lever is a bar made of tempered steel or light alloy. Several models are available, but all have the same basic design which includes a lift plate and a handle fitted with a rubber handle grip for greater safety. Small teeth on the front section of the lift plate dig into the stump and stop the lever from slipping out of the saw kerf. Some models have a cant hook to help with turning a stem or dislodging a hung-up tree.

Felling levers are commonly 80 cm (32 in.) long. Steel models weigh about 2.5 kg (5.5 lbs.); those made of aluminum alloy are lighter but not nearly as rugged.

Felling levers are commonly 80 cm (32 in.) long. Steel models weigh about 2.5 kg (5.5 lbs.); those made of aluminum alloy are lighter but not nearly as rugged.

How Do You Use It?

Properly used, a felling lever can help prevent the saw from getting jammed in the tree, and make it easier to push a tree over. It won't take the place of good notching and felling, but it can improve your chances of landing the tree where you want without back strain.

The lever is used after the notch is made and you're partly through the back cut. Stop sawing when there's enough space to insert the lift plate. Once in, it will prevent the tree settling back, closing the kerf and pinching the guide bar. Make sure the lever is pointing in the direction of fall, not at an angle.

The lever is used after the notch is made and you're partly through the back cut. Stop sawing when there's enough space to insert the lift plate. Once in, it will prevent the tree settling back, closing the kerf and pinching the guide bar. Make sure the lever is pointing in the direction of fall, not at an angle.

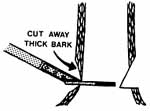

Place the lever at the middle of the back cut and in as far as possible to maximize leverage. If necessary, cut away any thick bark so the lever is supported by solid wood. Taking care not to let the chain strike the lever, complete the back cut. Be sure to leave an adequate hinge.

Now it's time to lever the tree over. To help distribute the load and to avoid strain, keep your back straight and knees bent --lift with your legs.

Keep both hands on the lever. When the tree begins to fall, always move back via the escape route.

Never push on the tree with one hand while lifting with the other. Lifting in a twisted position is a sure way to a serious back injury.

Never push on the tree with one hand while lifting with the other. Lifting in a twisted position is a sure way to a serious back injury.

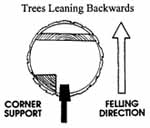

When felling trees upwind or against their natural lean, the felling lever can be invaluable. Cut a notch and make the back cut as illustrated. Be sure to leave a small unsawn corner for a support.

This will prevent the tree from settling back. Remove the saw and insert the felling lever. From the side of the tree, saw through the corner support at a downward angle to avoid hitting the felling lever. Lever the tree over as before.

Get into the habit of using a felling lever. As you work, carry or toss it from tree to tree. You won't need to use the lever with every tree, but it will be handy when you do.

Get into the habit of using a felling lever. As you work, carry or toss it from tree to tree. You won't need to use the lever with every tree, but it will be handy when you do.

Pulp Tongs and Hooks

Pulp tongs and hooks have made woods work considerably safer and more efficient. The inventors of these tools have created extensions of our hands. No longer do we have to jam unsuspecting fingers while trying to lift slippery pulpwood or wrench our backs trying to lift while bending awkwardly.

Tongs

Tongs

Tongs are used for grasping, holding or lifting pulpwood. Regular sized tongs can be used to lift wood with a diameter of up to 20-25 cm (8-10 in.).

Releasing the grip of the tongs from the wood requires a little practice. If they hold fast when you drop the wood, you or your tongs could end up on the pulp pile! To release the wood, use a quick pushing and twisting action. With practice, you'll learn quickly.

If you're willing to try the tongs even once, you'll understand why this tool has been so readily accepted by forest workers. Tongs come with a leather or vinyl holster which slips onto a belt for ready access.

Hooks

Hooks

The pulp hook is a curved steel hook mounted on a handle. 'Two types are available. One has been used in Atlantic Canada since the 1930s. It is designed to lift four-foot pulpwood (but it is frequently used with eight-foot wood). It is approximately 30 cm (12 in.) long with the hook perpendicular to the handle. On some models, the tip is replaceable.

The second type of pulp hook has a shorter history in Atlantic Canada. Used more frequently in Scandinavia than here, it was developed for rolling rather than lifting wood.

The second type of pulp hook has a shorter history in Atlantic Canada. Used more frequently in Scandinavia than here, it was developed for rolling rather than lifting wood.

In contrast to the previous larger hook, this one has the handle and the hook in the same plane. As a result, any piece of wood with a diameter greater than 15 cm (5.5 in.) will fall out of the hook when lifted. This hook is designed to roll wood and it comes with a holster to be worn on your belt.

This new hook is very good when used with modern silviculture systems. To learn its true advantages, however, you must commit yourself to learn how to use it. If you ignore the early frustrations, you will discover another valuable tool.

This new hook is very good when used with modern silviculture systems. To learn its true advantages, however, you must commit yourself to learn how to use it. If you ignore the early frustrations, you will discover another valuable tool.

Here are a few suggestion on using the smaller pulp hook:

-

Hold the handle closer to the edge to improve your grip on the wood.

-

Being flat on both faces, the hook can serve as an emergency wedge to stop the tree from settling back and jamming your saw.

-

With a suitable felling lever, you can increase the leverage on hung-up trees. (Be careful not to bend the or break the hook).

- Using the pulp hook with another hook or tong, you improvise a crude felling lever.

Two Hooks

With the influence of Swedish forestry methods in the province, several forest workers now use two hooks instead of pulp tongs. This approach requires improved technique and careful practice. Lifting is more efficient because the weight is more evenly distributed on the shoulders than when using one hand with the tongs.

The hooks are held on opposite sides of the pulpwood stick, and at a slight angle, as shown.

To reduce the chance of injury, try this cautiously at first, or get a demonstration.![]()

Sharpening

Sharpening these tools, especially the hook, is crucial. Without correct sharpening they will be next to useless. New tools are rarely sharp when sold , so follow this sharpening guide (excerpted with permission from forestry instructor Pekka Harkonen's The Chainsaw--Use and Maintenance).

For the pulp hook, file the inside of the point flat, so that it will grip the wood securely. The inside of the point should be parallel to the front part of the handle. Bevel the outer edges of the point to create the sharpness. The shape of the point ensures that the hook always bites into the wood.

For the pulp hook, file the inside of the point flat, so that it will grip the wood securely. The inside of the point should be parallel to the front part of the handle. Bevel the outer edges of the point to create the sharpness. The shape of the point ensures that the hook always bites into the wood.

To check if the point is properly sharpened, pull the hook across a flat, wooden surface with both hands. The point should always bite into the wood. To maintain the correct shape of the point, sharpen by filing the bevelled, otter edges.

Pulp tongs are sharpened in a similar manner.

Module 6 - Lesson Five Quiz

| Questions: | 10 |

| Attempts allowed: | Unlimited |

| Available: | Always |

| Pass rate: | 75 % |

| Backwards navigation: | Allowed |

Lesson Six - Limbing

LIMBING

Limbing is the systematic removal of branches from a felled tree. Time studies estimate that limbing takes approximately 50 per cent of the time a worker needs to harvest a tree. No doubt those who've harvested white spruce, otherwise called "cat or pasture spruce" will say the figure can be even higher! The fact that so much time is spent limbing means greater chances for accidents.

BASIC GUIDELINES

Modern safety-equipped chainsaws and protective clothing have helped reduce accidents and the severity of injuries. You can reduce the risk of limbing accidents by remembering these basic guidelines:

Create a Comfortable Working Height

Create a Comfortable Working Height

Plan your work to fell the tree so it's up off the ground. Use a "bench tree", wood pile, hummock, etc. Between knee and hip height is best. This will take the strain off your back.

Lower limbing, bucking, and handling is also easier!

Maintain a Firm Safe Stance

Keep you feet approximately shoulder-width apart and firmly on the ground. Bend your knees slightly.

Never straddle the tree or walk along the trunk. Maintaining your balance at all times is crucial for safe limbing.

Support the Saw

Support the Saw

Even light-weight chainsaws are heavy after a long day! Always rest the saw on or against the stem. Let the weight of the saw work for you by "levering" it to remove the branches.

Work Close To Your Saw

This is safer and more comfortable and provides better saw control. Never reach with your saw.

Maintain a Firm Grip

Maintain a Firm Grip

Chainsaws are designed to be used "right-handed." Always keep your left thumb around the front handle. This is important to maintain control of the saw if kickback occurs.

Use Full Throttle

For best results, run your saw at full throttle immediately before cutting. Do not hold the throttle wide open for long periods of time without putting it in wood, since this will damage the engine.

Avoid Cutting With the Tip

Use the flat sections of the guide bar. Dangerous kickback can occur when you limb (or buck) with the nose. Watch out for supporting stems and butt ends.

Clear Away Branches Safely

Clear Away Branches Safely

When moving cut branches, hold the saw by the front handle. This reduces the chance of accidentally hitting the throttle.

Never reach across the guide bar! Wait until the chain has stopped, and for added safety put on the chain brake.

Move Forward Safely

Move Forward Safely

Always keep the stem between you and the guide bar when moving forward.

Check for Branches Under Tension

When a tree is felled, branches are often placed under tension. You can avoid pinching your guide bar by making one or more cuts on the tension side first. Then cut the branch flush with the stem.

Top The Tree Safely

Never reach forward and top the tree by pulling the saw toward yourself. Take the extra step and make this last cut safely to avoid possible kickback. It's a step that may save your life.

Workers have been killed because the saw has kicked back and cut the artery along the inside of their leg.

TECHNIQUES

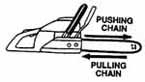

First let's distinguish between "pushing" and "pulling" chain. The pushing chain refers to the chain on the top of the guide bar while the  pulling chain refers to the chain on the underside.

pulling chain refers to the chain on the underside.

Lever Method

With the lever method, two important points must be emphasized. First, the saw must be used as a lever while limbing and secondly, the weight of the saw should rest on the stem, not your back. Saw position and work stance permit levering (or pivoting) the saw without any wasted effort. The saw body rests against the stem and your thigh as necessary. The same firm safe stance is used for all six steps.

The lever method works well on stems with closely spaced branch whorls. Always remember to use full throttle.

Step 1

Step 1

Rest the saw on the tree with the guide baron the right side. Use the pushing chain to cut all branches in section 1.

Step 2

Tilt the saw toward yourself, resting the guide bar on top of the stem. Lever the saw using the pushing chain to remove branches in section 2. You may need to lean slightly to the left to make room for the saw.

Step 3

Shift the saw into an upright position. Support the saw body between the tree and your right thigh. Use the pulling chain to cut limbs in  section 3.

section 3.

Step 4

Bring your body weight forward and lever the saw upwards to cut branches in section 4 with the pushing chain. Use your bent knees to help push the saw forward.

Step 5

Shift the saw onto its right side, resting on top of the stem. Lever the guide bar to cut branches in section 5 with the pushing chain. Change your grip to suit the position of the saw. You'll need to use your thumb on the throttle.

Step 6

Step 6

Return the saw to an upright position, still supporting the saw on the tree. Use the pulling chain to saw downward and remove branches in section 6.

Now, with the saw resting on the tree and guide bar on the opposite side of the stem, it is safe to move forward and begin step 1 again. Follow this six step pattern for the whole length of the tree.

Very few trees will fit this perfect example requiring six steps on every section. Missing branches will allow you to skip some of the steps while branches under tension must be cut separately to avoid jamming the saw. Common sense must be applied when using the lever method.

Sweep Method

Sweep Method

With the sweep method, limbs are removed with a sweeping motion in three phases.

It is particularly suited to trees with many small-diameter branches (common in dense stands) or with unevenly spaced branch patterns.

Step 1

Start with the saw on the left side of the stem. Maintain a balanced stance (similar to the lever method) and support the saw against your right thigh. Make a forward sweep using the pushing chain. Avoid overreaching with the saw and placing strain on your back.

Step 2

Tilt the saw on top of the stem and sweep backward using the pulling chain.

Step 3

Now, tilt the saw with the guide bar down on the right side of the stem. Support the saw on the tree and make a forward sweep using the pushing chain.

Keep the saw on the right side while you move forward. Change the saw to the left side and begin step 1 again. You can use the first three steps of the lever method to bring the saw back to the left side.

Removing Bottom Branches

Removing Bottom Branches

Generally, limbing bottom branches can be done as each sequence of steps is finished or after the entire tree has been limbed. With the tree at a comfortable working height, lower limbing is much easier and all the branches can be removed in one pass down the tree.

If you prefer lower limbing after each sequence, face the stem and make a short sweep backwards using the pushing chain.

Ensure the bar is flush with the underside of the stem. Support your right forearm or elbow against your right thigh and avoid overextending.

If the stem is close to the ground, top and roll to expose the remaining branches. Then, use the pulling chain while moving backward in small steps. Support the saw on the trunk and always maintain a firm footing. Watch out for hidden stumps or rocks which may damage the chain or cause kickback.

Module 6 - Lesson Six Quiz

| Questions: | 10 |

| Attempts allowed: | Unlimited |

| Available: | Always |

| Pass rate: | 75 % |

| Backwards navigation: | Allowed |

Lesson Seven - Bucking

BUCKING

Bucking is cutting a fallen tree into logs or smaller products. These may include sawlogs, studwood, pulpwood, fuelwood, fence posts, etc. Bucking enables easier handling of raw wood products during piling, extraction, and trucking. By knowing and following wood quality standards for lengths, grades, or species you can maximize utilization.

When a stem is supported evenly on the ground, a single cut may be all that's needed. However, a fallen tree is often under tension, posing a risk to both you and your saw. A frequent problem occurs when the guide bar binds in the cut, resulting in a severely pinched bar or nose sprocket.

BASIC GUIDELINES

Bucking can also expose you to some potentially dangerous situations. You can minimize the risk of bucking accidents by following these basic guidelines:

Check the work area

Clear away any debris that might interfere with bucking. Look for objects (eg. piled wood) that could cause kickback. On uneven ground, always stand on the uphill side.

Assess the tension

Examine the stem to see where it is supported and how it is bent. This will help you avoid potential problems.

Maintain a firm safe stance

Maintain a firm safe stance

Keep your feet approximately shoulder-width apart and firmly on the ground. For balance, position your left foot slightly ahead of your right foot. This safe stance will allow you to move quickly if the stem suddenly rolls or settles.

Work close to your saw

Keep your arms in a comfortable position - not out-stretched. Maintain a firm grip and always keep your left thumb around the front handle

Avoid cutting with the tip

Avoid cutting with the tip

Use the flat sections of the guide bar and practice good bar tip control. A high percentage of chainsaw injuries are caused by kickback.

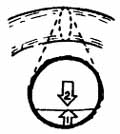

With any stem there will always be a "compression" and a "tension" side.

With any stem there will always be a "compression" and a "tension" side.

Examine a bent stem. The inside of the bend is the compression side. Stress will cause this area to compress when cut and bind the saw. Always cut on the compression side first!

The area on the outside of the bend will pull apart when cut. This is the tension side. If you decide to cut this side only, the tree will split apart before the cut can be completed.

The area on the outside of the bend will pull apart when cut. This is the tension side. If you decide to cut this side only, the tree will split apart before the cut can be completed.

CUTTING TECHNIQUE

First make a cut on the compression side ' approximately 1/3 of the stem's diameter.

First make a cut on the compression side ' approximately 1/3 of the stem's diameter.

This will usually leave enough wood to keep the stem from pinching the guide bar. Use full throttle. Finish the cut by sawing through from the tension side. You will notice the saw kerf open as you complete this cut.

It is often difficult to determine where the pressure is in a log. Compression (C) and tension (T) areas are identified below in three of the most common situations.

1. supported at one end

1. supported at one end

2. supported at both ends

3. supported at one point along the stem.

Side Bend

The above procedure is the same for stems bent to one side. However, there is a greater risk of injury. Always stand on the inside of the bend (ie. compression area). When the second cut is made the stem will spring out away from you. Always remain alert.

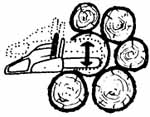

BORING CUT

BORING CUT

The boring cut is a valuable technique for bucking logs piled together that cannot be moved. To avoid kickback, start with the bottom tip of the guide bar.

Be sure to hold the saw firmly. Once the cut is sufficiently deep, lift the saw to a horizontal position and bore straight into the stem.

Be sure to hold the saw firmly. Once the cut is sufficiently deep, lift the saw to a horizontal position and bore straight into the stem.

Complete the cut by moving the saw up and down as required.

SPRING POLE

A spring pole is a sapling that has been bent over by another tree.

The resulting shape is an upside down "U". Frequently encountered in forestry operations, the spring pole is under tremendous pressure and if cut incorrectly, whips up with considerable force. Although rarely fatal, it is responsible for a few bruises, scars and broken bones.

The resulting shape is an upside down "U". Frequently encountered in forestry operations, the spring pole is under tremendous pressure and if cut incorrectly, whips up with considerable force. Although rarely fatal, it is responsible for a few bruises, scars and broken bones.

Before attempting to cut the spring pole, first check to see if the felled tree can be removed by a farm tractor or other machine working nearby.

To cut the spring pole, start at the base of the stem and make a series of shallow cuts on the inside of the bend.

Fast, shallow cuts are recommended to avoid jamming the guide bar while releasing some of the tension. With each cut you'll see the force of the spring pole being released. Avoid using the tip of the bar.

Next, make a final release cut on the opposite side of the stem and below the lowest inside cut. This technique will prevent the sapling from forcefully pushing out your saw.

Next, make a final release cut on the opposite side of the stem and below the lowest inside cut. This technique will prevent the sapling from forcefully pushing out your saw.

Stand to the side of the tree and never in the line of travel of the cut stem.

Stand to the side of the tree and never in the line of travel of the cut stem.

WINDFALLS

WINDFALLS

Windfalls or uprooted trees often pose another serious hazard for forest workers. Misjudging compression and tension areas in the tree will result in your saw becoming jammed. If the stem has an upward bend, make the top cut first. Saw through approximately 1/3 of the diameter. Remember to withdraw the guide before it pinches. Then complete the cut by sawing through from below.

If the stem has a downward bend, reverse the cutting sequence.

If the stem has a downward bend, reverse the cutting sequence.

Never work beneath an over-hanging root mass. Begin working carefully, limbing and bucking from the top of the windfall. Watch for any sudden movement. Leave a long enough butt log and then have the machine operator lower the root section with the winch. Fell the butt log in the usual manner.

Occasionally a tree will break, but with the top still attached. Never work beneath the top. When a machine is nearby, let the operator pull it down for you.

Occasionally a tree will break, but with the top still attached. Never work beneath the top. When a machine is nearby, let the operator pull it down for you.

If a machine is not available, begin by limbing from the top and bucking off lengths. Don't limb above shoulder height. Then, using the felling lever, roll the remaining stem to the ground. Fell the remaining stub in the usually manner.

If a machine is not available, begin by limbing from the top and bucking off lengths. Don't limb above shoulder height. Then, using the felling lever, roll the remaining stem to the ground. Fell the remaining stub in the usually manner.

Always select a suitable escape route and make sure it's clear of obstacles.

Always select a suitable escape route and make sure it's clear of obstacles.

MEASURING FOREST PRODUCTS

While bucking trees, it is important to cut the products into proper lengths.

Generally, bucking specifications are provided by the person or company purchasing the product. It is the responsibility of the cutter to know these specifications and apply them correctly.

Several things can be used to assist with the accuracy of bucking. They include:

- loggers tape or measuring tape

- a plastic measuring tail (whip, wand) attached to the saw

- the chainsaw

- measuring pole

Once measured, the bucking cut can be performed as discussed.

Module 6 - Lesson Seven Quiz

| Questions: | 10 |

| Attempts allowed: | Unlimited |

| Available: | Always |

| Pass rate: | 75 % |

| Backwards navigation: | Allowed |

Lesson Eight - First Aid

FIRST AID

First Aid is a combination of knowledge, skills and attitudes which must be learned and practised before emergencies arise. First Aid saves lives, relieves suffering and reduces the cost of accidents.

The contents of this lesson are taken from the St. John Ambulance book " Emergency First Aid Safety Oriented ". The lesson does not constitute a First Aid course, neither does it meet a recognized standard of First Aid training. Certified First Aid training is available through St. John Ambulance courses and the Red Cross Society. However, the lesson does contain some of the basic and simple First Aid that could relieve suffering or even save a life - maybe your own.